Most of the time when you’re out on the golf course, you’re focused on perfecting your swing or enjoying the beautiful scenery. But have you ever stopped to think about what those small, dimpled balls are actually made of? Let’s examine the fascinating world of golf ball materials and construction to uncover the secrets behind this vital piece of equipment for every golfer.

Key Takeaways:

- Composition: Golf balls are typically made of a solid core, rubber thread, and a molded cover material.

- Materials: The core can be made of solid rubber or synthetic materials, the thread is usually rubber, and the cover can be constructed from various materials like ionomer or urethane.

- Impact on Performance: The materials used in golf ball construction can affect factors such as distance, spin, and feel, making it important for golfers to choose the right ball for their game.

The Core of the Matter

Rubber Core Composition

For the heart of a golf ball, you’ll find a rubber core that serves as the foundation for its performance on the green. This core is typically made of a synthetic rubber material that provides the necessary weight and compression for optimal distance and control. The composition of the rubber core is carefully engineered to ensure a perfect balance between softness and resilience.

Core Size and Shape

To enhance your game, the size and shape of the core play a crucial role in determining the overall performance of the golf ball. The core is strategically designed to maximize energy transfer upon impact, translating into longer drives and more precise shots on the course. Manufacturers meticulously craft the size and shape of the core to meet the specific needs of different types of golfers, whether you are a beginner or a seasoned pro.

Size matters when it comes to the core of a golf ball. A larger core allows for more energy storage and transfer, resulting in greater distance off the tee. On the other hand, a smaller core offers more control and spin, ideal for finesse shots around the green. Manufacturers tailor the size of the core to suit different swing speeds and playing styles, ensuring that you can find the perfect fit for your game.

Composition

In terms of the core of a golf ball, the composition is key to unlocking its full potential on the course. The materials used and the technology behind the core can significantly impact your performance, providing the right balance of distance, control, and feel. By understanding the composition of the core, you can make an informed decision when choosing the perfect golf ball to elevate your game.

The Mantle Layer

Now, let’s investigate the mantle layer of a golf ball, which plays a crucial role in its performance. This layer is situated between the cover and the core of the golf ball and is typically made of synthetic rubber blends.

Synthetic Rubber Blends

Synthetic rubber blends are commonly used in the mantle layer of golf balls due to their durability and resilience. These materials are designed to enhance the ball’s overall feel and control, allowing you to achieve better shots on the course.

Material Properties and Functions

One key property of synthetic rubber blends in the mantle layer is their ability to provide a consistent transfer of energy upon impact. This helps ensure that your shots are powerful and accurate, giving you the precision you need to improve your game.

It is also worth noting that the mantle layer helps to control the spin of the ball, especially on longer shots. This control is vital for maintaining stability and achieving the desired trajectory during your game.

The Cover Layer

Keep in mind that the cover layer of a golf ball plays a crucial role in its performance. This outer layer directly impacts the feel, spin, and durability of the ball. There are mainly two types of materials used for the cover layer of golf balls: Surlyn and Urethane.

Surlyn and Urethane Materials

The choice between Surlyn and Urethane cover materials affects the characteristics of the golf ball. Surlyn covers are often found in two-piece golf balls, providing durability and distance with a firmer feel. On the other hand, Urethane covers are featured in higher-end balls, offering better spin control and a softer feel for more skilled players. Depending on your playing style and preferences, selecting the right cover material can significantly impact your game.

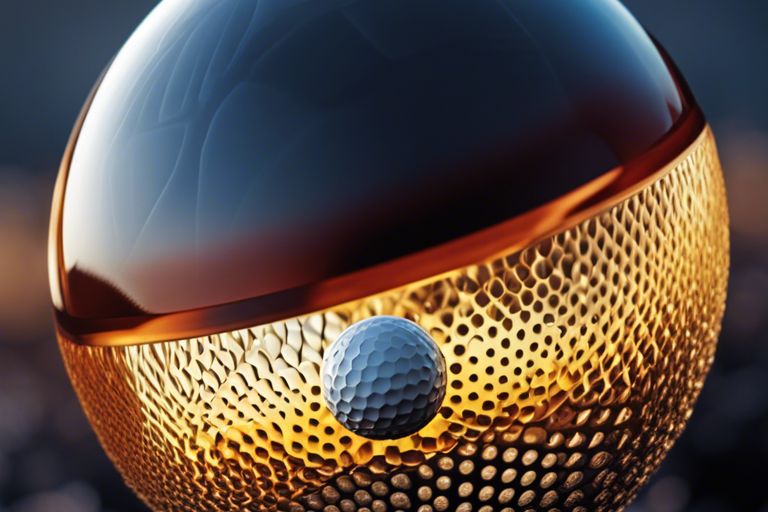

Dimple Patterns and Aerodynamics

With advancements in technology, golf ball manufacturers have engineered dimple patterns on the cover layer to optimize aerodynamics. Different dimple configurations are designed to reduce drag and improve lift during flight, ultimately enhancing distance and accuracy. The dimple pattern on a golf ball is not just for aesthetics; it plays a vital role in how the ball performs through the air.

A golf ball with a dimple pattern that is carefully optimized can result in a more consistent and stable flight trajectory. Next time you’re on the course, pay attention to the dimple design on your ball and how it influences its performance as it soars through the air.

Additional Components

Despite the core and cover being the main components of a golf ball, there are additional materials that play a crucial role in the construction of these sports necessarys. These additional components include fillers, reinforcements, pigments, and colorants.

Fillers and Reinforcements

One important aspect of golf ball construction is the use of fillers and reinforcements. Fillers like zinc oxide or titanium dioxide are often added to the rubber core mixture to enhance durability and provide specific playing characteristics. Reinforcements, such as rubber threads or a woven layer, are also incorporated to improve strength and maintain the shape of the ball during impact.

Pigments and Colorants

Colorants are added to the materials used in golf balls to give them their distinctive appearance. This component allows manufacturers to produce balls in a variety of colors, making them more visually appealing to golfers. Additionally, pigments are used to provide specific color shades and patterns, adding a touch of personalization to the golf ball.

This attention to detail in the coloring of golf balls not only adds aesthetic value but also serves functional purposes. For instance, bright colors like orange or yellow can make the ball more visible on the golf course, especially in low light conditions. This can help you track the ball more easily and save time searching for it after a shot.

Manufacturing Process

Injection Molding and Compression

Unlike the traditional wound golf balls, modern golf balls are typically made using a process called injection molding or compression. In this process, a heated mixture of rubber and other materials is poured into a mold. The mold is then closed, and the mixture is compressed into the desired shape of the golf ball. Once the ball is formed, it is cooled and removed from the mold.

Winding and Curing

An alternative method used for making golf balls is winding and curing. In this process, a long elastic thread is wound around a small core. The wound core is then coated with layers of rubber and materials to create the outer cover of the golf ball. The ball is then cured, which helps to set the materials and give the ball its final shape.

It is important for manufacturers to carefully control the winding and curing process to ensure that the golf ball has the right balance of hardness, elasticity, and durability. This process allows for the customization of the golf balls to meet the specific performance needs of different golfers.

Quality Control and Testing

Not only are the materials used in the construction of a golf ball important, but the quality control and testing processes are also crucial in ensuring a consistent and high-performing product. Manufacturers follow strict guidelines to ensure that every golf ball meets certain standards before it reaches your hands.

Weight and Size Regulations

Control over the weight and size of a golf ball is imperative in maintaining fairness and consistency in the game. The rules set by organizations like the USGA dictate that a golf ball must not weigh more than 1.620 ounces and have a diameter of at least 1.680 inches. During production, golf balls undergo meticulous testing to ensure they meet these regulations, guaranteeing a level playing field for all golfers.

Performance and Durability Tests

Quality control measures extend beyond just weight and size. Golf balls also undergo rigorous performance and durability tests to ensure they meet the standards for distance, spin, and durability. These tests involve launching the balls at high speeds, simulating different weather conditions, and subjecting them to intense pressure to assess their performance under various circumstances. Only golf balls that pass these tests with flying colors make it to the market, giving you the confidence that you’re playing with a top-quality product.

To ensure that every golf ball you purchase meets the highest standards of quality and performance, manufacturers invest heavily in quality control and testing processes. From checking weight and size regulations to testing performance and durability, every aspect of a golf ball is scrutinized to deliver a product that helps you play your best game on the course.

Summing up

Now that you know what golf balls are made of, you can impress your friends with your newfound knowledge about the composition of this crucial piece of golf equipment. From the core to the cover, each layer plays a crucial role in how the ball performs on the course. So, the next time you tee up, think about the materials that make up your golf ball and how they contribute to your game. Happy golfing!

FAQ

Q: What are golf balls made of?

A: Golf balls are typically made of a solid core (usually made of synthetic rubber or resin), surrounded by one or more layers of a durable cover material. The cover is usually made of a blend of materials such as Surlyn, Urethane, or Balata.

Q: Are there different types of golf balls based on their materials?

A: Yes, there are different types of golf balls based on their construction materials. For example, two-piece golf balls have a solid core and a cover, while multi-layer golf balls have additional intermediate layers between the core and cover to enhance performance.

Q: What is the importance of the materials used in golf ball construction?

A: The materials used in golf ball construction play a crucial role in determining the ball’s distance, spin, feel, and durability. Different materials can impact the ball’s performance characteristics, such as softer covers providing more spin control, while harder covers may offer more distance.